on Posted on Reading Time: 4 minutes

Recap the Goals

As described in the MEF Edge VIEW Blog post, Extreme Slicing and Japanese Beaches: Highlights from MEF 3.0 PoC Showcase 2021, more enterprises are increasingly considering using private 5G and network slicing as part of their digital transformation. The combination of very low-latency, wireless connectivity available with 5G, powerful compute, and Multi-Edge Access Computing (MEC) is opening up a wide range of new use cases in many industries.

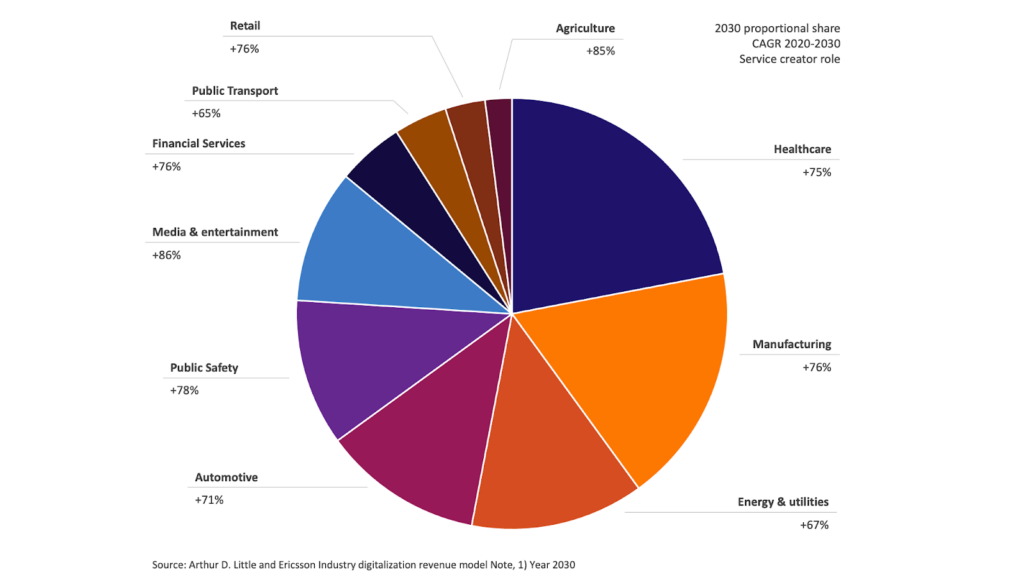

Figure 1 shows the share and growth rate for service providers from 5G business-to-business (B2B) opportunities and demonstrates that these industries are expected to have significantly larger markets in 2030, with manufacturing and healthcare being the largest market segments.

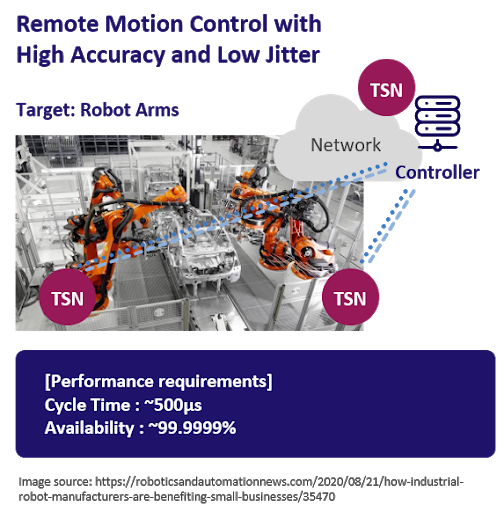

As an example, manufacturing, or Industry 4.0, will use network slicing over 5G to enable precise remote motion control for robots and AGVs (Automated Guided Vehicles) in a smart factory, as well as disaggregated computing.

TSN (Time-Sensitive Network) Communication

One of the typical and critical use cases in a smart factory is remote control of AGVs. The AGV can be, not only a vehicle, but also a machine tool. When AGVs can be controlled remotely with private 5G and network slicing, the weight and batteries of the AGV can be significantly reduced, and the operational time lengthened. These improvements increase the productivity, efficiency, and profitability of the factory. To control the AGVs remotely, the Service Provider must be able to handle several types of data traffic for applications, such as image analysis for motion control, and data analysis for real-time corrections.

To remotely enable precise robot or AGV motion control via a private 5G network, TSN provides exact packet transmission scheduling at µs granularity in the local network, so that normal delay variations are in the order of nanoseconds. By using network slices, TSN communications are enabled at the same delay variation as the local network even if it is through a WAN.

MEF 3.0 PoC (138) shows how to achieve such extremely low latency and jitter-less communications over end-to-end network slices.

Disaggregated Computing

Another promising use case of end-to-end slicing for Industry 4.0 is disaggregated computing. As disaggregation of server hardware in the data center increases, server hardware like CPU, GPU, Storage, and NIC is being connected over the network using technologies such as Remote Direct Memory Access (RDMA)─equivalent to a computer internal bus over the network, such as PCI-express.

RDMA can transfer data from the memory of a local computer to the memory of a remote computer. An example of network performance requirements for disaggregated computing is more than 4 GB/s throughput for data transfers between memory and storage, with time synchronicity of less than 10 µs for parallel processing between CPUs.

By combining RDMA with network slicing over 5G, the storage requirements can be distributed out of the robots and AGVs, and into the next-generation data center, which in turn can be distributed between the factory and the service provider’s edge.

In the MEF 3.0 PoC (138), we demonstrate how to achieve very large data transfers from local CPUs to remote storage using RDMA over end-to-end network slices.

Two Critical Technology Enablers

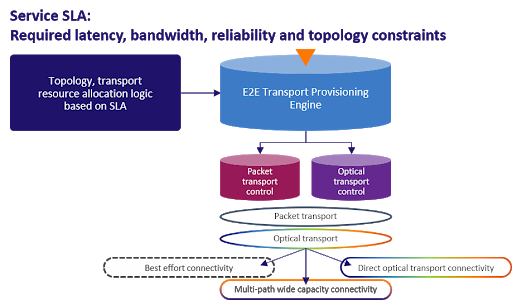

Multi-layer Transport Provisioning Engine (MLTPE) enables optimal transport-resource provisioning for both packet and optical networks in accordance with an SLA. MLTPE is implemented to work with the ONF TAPI Reference Implementation and MEF LSO Presto APIs to control connectivity services through Element Control and Management (ECM), such as packet domain controllers and optical domain controllers.

The MLTPE is utilized to calculate the optimal resources and paths for transport slices to meet the ultra-high-performance requirements of mission-critical applications.

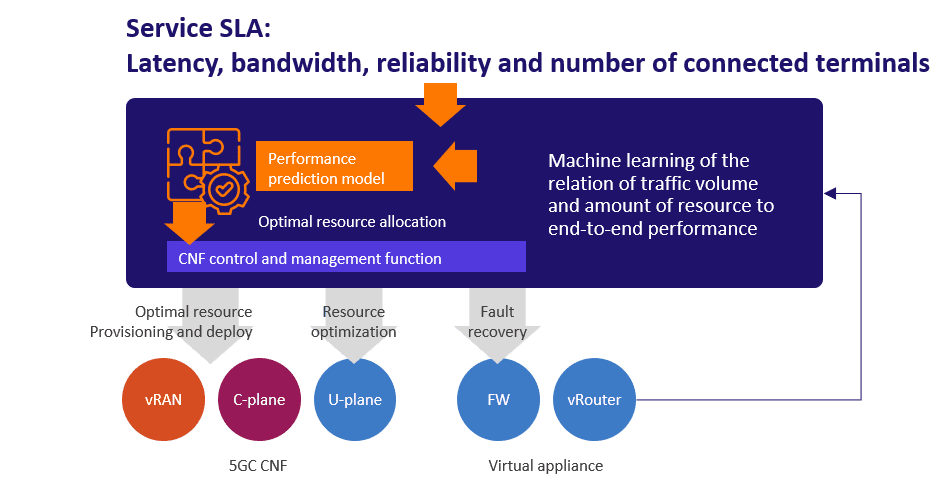

Automated Cloud-native network function Provisioning Engine (ACPE) enables automated optimal container resource allocation for CNFs. It sets up the optimal allocation of server resources for a specific SLS. The optimized set of virtualized resources such as CPUs, memory, NIC, and GPUs are allocated to assure ultra-high performance of 5G network slices.

The performance for CNFs is predicted by an ML-based model, performs optimal resource calculations, and continuously updates itself in line with traffic changes. It also supports the multi-cluster deployment of CNFs for low-latency and reliability, based on the calculations of the ACPE.

ACPE works with many container control and operation software packages, such as Helm and Kubernetes operator for instantiation, modification, scaling, and deletion of 5G network slices.

Learn More

Also read our other blog post: Extreme Slicing and Japanese Beaches

Read more about: MEF 3.0 PoC (138) E2E Slicing for Extreme Services

This PoC was presented at the MEF PoC Showcase in Q1 2021. Watch the Presentations on YouTube

About MEF’s PoC Program & Showcase

The MEF 3.0 Proof of Concept program effectively fosters innovation, seeds new MEF standards and projects, and accelerates our existing work within the ICT industry by providing our members—including service providers, technology suppliers, and other stakeholders within the ICT industry—the opportunity to collaborate on MEF 3.0-based use cases throughout the year.

Initiated by MEF members and facilitated by MEF staff, each MEF 3.0 PoC receives a unique, identifying number that remains unchanged as its title and messaging evolves over the life of the project.

PoC work is highlighted in public showcases and award presentations that explore individual Proofs of Concept. Learn more about these enabling technologies and the MEF 3.0 PoC Program.

About MEF’s PoC Program & Showcase

The MEF 3.0 Proof of Concept program effectively fosters innovation, seeds new MEF standards and projects, and accelerates our existing work within the ICT industry by providing our members—including service providers, technology suppliers, and other stakeholders within the ICT industry—the opportunity to collaborate on MEF 3.0-based use cases throughout the year.

Initiated by MEF members and facilitated by MEF staff, each MEF 3.0 PoC receives a unique, identifying number that remains unchanged as its title and messaging evolves over the life of the project.

PoC work is highlighted in public showcases and award presentations that explore individual Proofs of Concept. Learn more about these enabling technologies and the MEF 3.0 PoC Program.